[ad_1]

In a improvement that may quickly render snow shovels and salt redundant, Drexel University researchers have unveiled a self-heating concrete expertise poised to rework winter infrastructure in chilly areas.

This progressive concrete, infused with phase-change supplies, can autonomously preserve heat, successfully keeping off snow, sleet, and freezing rain.

This development guarantees important reductions in each the environmental and financial prices related to winter climate administration. Moreover, it extends the lifespan of concrete surfaces by stopping the wear and tear and tear brought on by freeze-thaw cycles and deicing chemical compounds.

Proof on campus

Positioned on Drexel College’s campus, two experimental concrete slabs have been efficiently demonstrating this expertise for over three years.

These slabs, every measuring 30 inches by 30 inches, have persistently resisted winter’s harshness with none guide intervention. They showcase the potential for a future the place icy sidewalks and roads are issues of the previous.

The science of self-heating surfaces

The driving power behind this innovation is the need to create infrastructure that’s each environmentally pleasant and resilient in opposition to the trials of northern winters.

The USA, significantly its northern area, spends billions yearly on snow and ice elimination, to not point out the substantial prices of repairing winter-damaged roads.

In accordance with Dr. Amir Farnam, affiliate professor at Drexel’s Faculty of Engineering, the important thing to prolonging the lifetime of concrete surfaces lies of their capacity to stay above freezing temperatures throughout winter, thus eliminating the detrimental freeze-thaw cycles.

Bringing self-seating concrete into the actual world

Over 5 years, Dr. Farnam’s workforce refined the self-heating concrete combine to minimize the necessity for plowing and salting. Their breakthrough confirmed its effectiveness in real-world situations, due to low-temperature liquid paraffin.

This phase-change materials releases warmth in the course of the liquid-to-solid transition, permitting the concrete to take care of floor temperatures between 42- and 55-degrees Fahrenheit for as much as 10 hours in freezing conditions. This prevents ice formation and melts snow effectively.

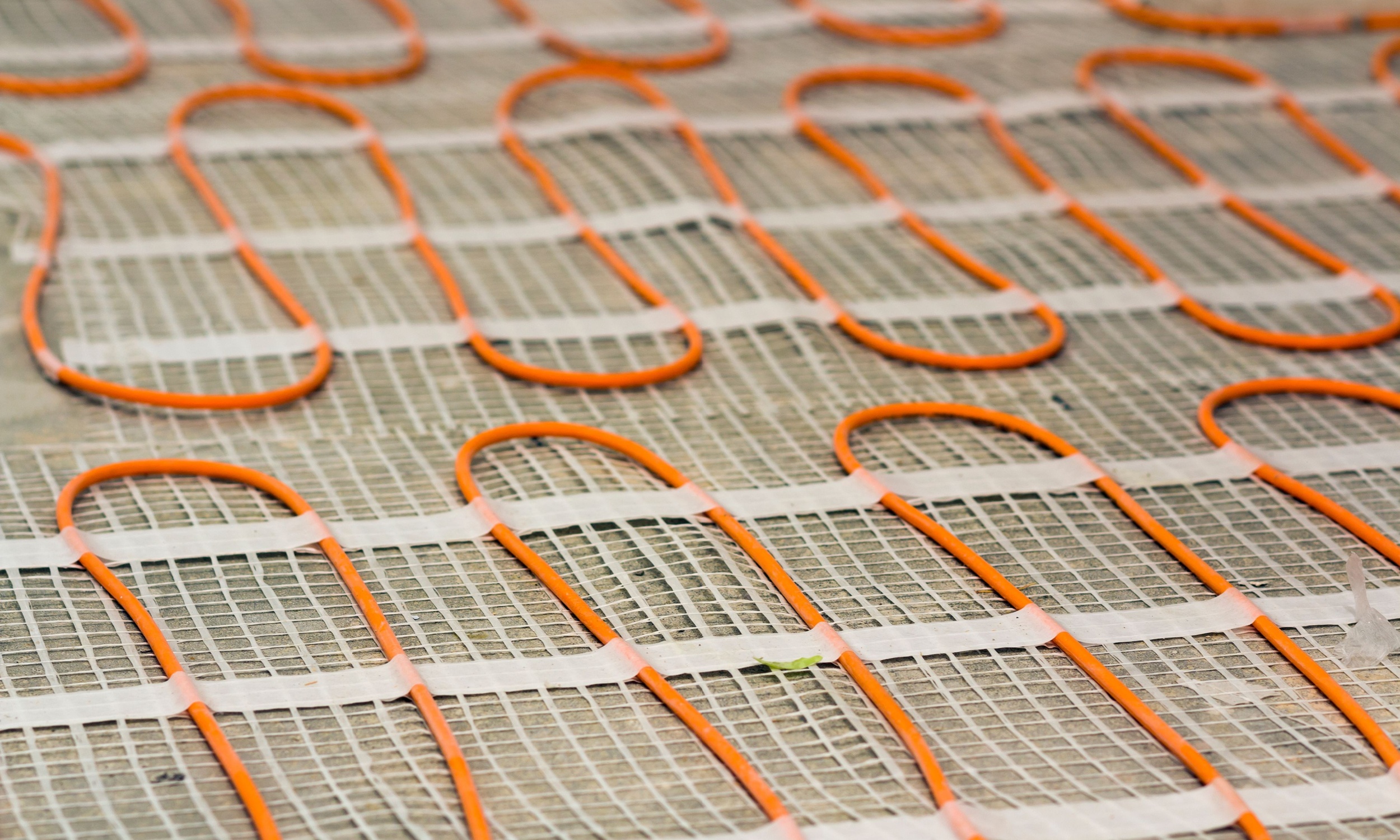

The researchers examined two strategies for including phase-change materials to concrete. The primary technique concerned pre-treating light-weight combination with paraffin. The second technique concerned mixing micro-capsules of paraffin immediately into the concrete.

Over two years and thru 32 freeze-thaw occasions and heavy snowfalls, each strategies efficiently saved floor temperatures above freezing. This prevented the structural injury usually brought on by enlargement and contraction.

Evaluating heat

The examine revealed two key findings about concrete with phase-change supplies. Concrete incorporating phase-change materials in light-weight combination sustained heat longer. Conversely, concrete with microencapsulated paraffin warmed up quicker but in addition cooled down extra shortly.

This means the previous is best for deicing, releasing warmth slowly, particularly in sub-zero temperatures.

Nonetheless, effectiveness varies with elements like ambient temperature and snowfall price. Though the self-heating concrete can’t absolutely forestall heavy snow accumulation, it’s very efficient for snowfalls beneath two inches, offering a greener various to street salting.

Steady enchancment and long-term affect

Because the Drexel workforce continues to refine this expertise, their analysis underscores the potential of self-heating concrete to considerably cut back the incidence of freeze-thaw cycles, enhancing the sturdiness of concrete surfaces in comparison with conventional supplies.

This promising improvement marks a big stride towards extra sustainable and resilient infrastructure able to withstanding the challenges of winter climate.

The examine is revealed within the journal Materials in Civil Engineering.

—–

Like what you learn? Subscribe to our newsletter for participating articles, unique content material, and the most recent updates.

Examine us out on EarthSnap, a free app dropped at you by Eric Ralls and Earth.com.

—–

[ad_2]

Source link